How To Avoid Lippage When Installing Flooring

Lippage is a common tiling error that can result in unsightly results. Here’s how to avoid it.

What is Lippage?

Lippage refers to an uneven floor surface caused by tiles that are not laid at a uniform level. It occurs when one tile is higher or lower than its adjacent tile and is more likely when dealing with large format or wood-look plank tiles.

When looking at the image below, notice how some tiles seem higher than others. The tile planks don’t form a flat and even surface.

Lippage is a serious matter because other than being unsightly, it can be a tripping hazard. These differences in height or perception of differences are influenced by many factors such as:

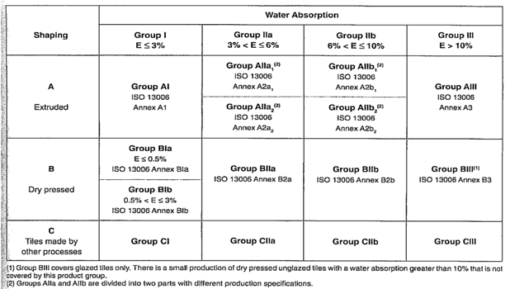

- Actual allowable thickness variation of the tiles when judged in accordance with manufacturing standards.

- The allowable warpage of the tile modules.

- The spacing or separation of the tiles, which would influence a gradual or abrupt change in elevation. This is essentially the thickness of the grout lines.

- The angle of natural or artificial light accentuating otherwise acceptable variance in modules. The customer sees what appears to be serious lippage but it is in fact just shadows cast by low angle light.

- Highly reflective surfaces in the tile accentuating otherwise acceptable variance in the modules. Similar to the above but caused by reflective properties of the tiles.

- Poor installation. This is by far the most common cause of lippage. If the subfloor is uneven, if inadequate adhesive has been used to bed the tiles, if grouting is too thin, or if the tiles have simply not been bedded down correctly. All these can lead to lippage.

Although tiles may look flat at first glance, if you look closely, they probably aren’t. This is not to say they don’t conform to the international standards (warpage), but the very shape of these tiles makes their flatness all the more critical. Basically, with these tiles, the centre is higher, i.e. they are crowned in the middle. This becomes more of a problem when you offset (overlap) them. Variation should not exceed 2mm (depending on size of tile) over the length but this is still enough to cause problems.

Test warpage by putting two tiles face-to-face and you can see how much bowing there is and measure it. Typically, allowable warping is half a percent of the length. So, for a 1,2m plank tile the allowable warpage is 6mm.

The 3 Hazards of Lippage

- Lippage Can Be Grounds for an Installation Job to Be Rejected

One or more of the tile standards has been violated and can be grounds for the job to be rejected.

- Lippage Can Lead to Serious Injury

A serious injury may occur if someone trips on the high tile. In this case, the installer is responsible if someone falls and could be involved in a lawsuit.

- Lippage Looks Bad

And finally, it looks really bad for the installer, to the customer and for the entire tile industry. In the photo below, you see evidence of lippage where the movement of the chair leg across the high tile edge has caused it to chip in several places. As it is, the floor has become an eyesore.

How to Avoid Lippage

-

Subsurface flatness

If the sub floor isn’t really flat, any variation will be accentuated in the tiles. The subfloor should have no greater variation than 6mm in 3m. Also, the larger the tile, the greater the reflection of the unacceptable subsurface tolerance will show up as increased lippage in the finish. The subsurface tolerance is probably the tile contractor’s biggest concern with regards to lippage.

Generally, surface prep is the first step to avoiding lippage. It’s truly critical to ensure that the substrate is flat before installing tiles.

Surface prep, whether it is wall or floor is critical to the completed job being acceptable to the end user. If the substrate is not flat, the finished surface will mirror the irregular substrate which is especially true when tiles are installed over concrete block walls as you see in the photo above.

If your floor isn’t flat this will accentuate the problems with the crown of the tiles.

-

Offset

By doing a 50% offset, where the middle of a tile is exactly in line with the grout joint of the next row, you maximise the amount of unevenness, or lippage, between the tiles. In fact, unless the tile manufacturers say otherwise, the American National Standards Specifications for the Installation of Ceramic Tile sets the limit at 33% (one third) maximum offset. This means that on a 600mm long tile the maximum offset is 200mm.

A wider stagger might cause lippage, because longer tiles are often crowned in the middle.

If you have any question about Lippage, you are most welcome to contact our Tiletoria Showroom’s to speak to our experts. Our experts offer technical training that is available online or in office with your architectural team. We are also SAIAT accredited to issue CPD credits.