What are Movement & Perimeter joints?

A movement joint, also known as a soft joint, is the interruption of the surface to allow for movement. Simply put – a movement joint is a gap or space next to a tile that lets a tile floor move a bit. There are two kinds of movement joints: expansion (movement) and perimeter.

A movement or expansion joint is usually a grout joint that is left ungrouted. Usually it gets filled with a flexible caulking (this sealant must be 100% silicone, urethane or polysulfide) that matches the grout colour so that you don’t even see the movement joint.

Selection of movement joint type will depend on joint width requirement, finished floor use and movement capability. The range of materials available and their typical area of use include: aluminium for general commercial installation; brass or stainless steel for heavy commercial and industrial use; and PVC for most other applications. This ungrouted grout joint would have to extend from wall-to-wall to be effective.

Perimeter joints are the kind that every tile installation should have. When you place a tile up to (abuts) a wall, it should have a gap (minimum of 5mm) between it and the wall. There should be a gap around the entire floor (or wall). This gap must be free of any adhesive or debris. Typically, this gap doesn’t get filled with anything.

Why Do You Need Expansion Joints When Installing Tile?

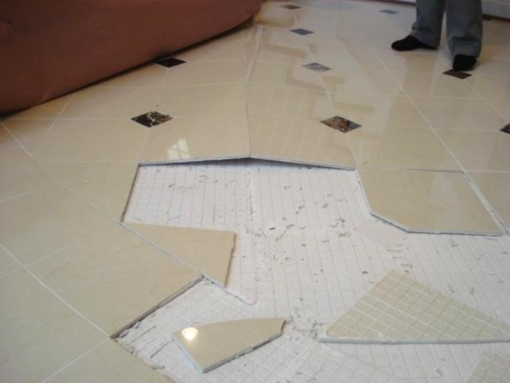

The reason they are so critical is that without them, most installations which otherwise appear to be well done, can fail. Without enough room for the tile assembly to expand, the tile/s will pop up or “tent” most times in the middle of the floor. This situation can occur in both commercial as well as residential jobs.

Here is an unfortunate example of tiles ‘tenting’:

Expansion joints are not optional – they are a requirement.

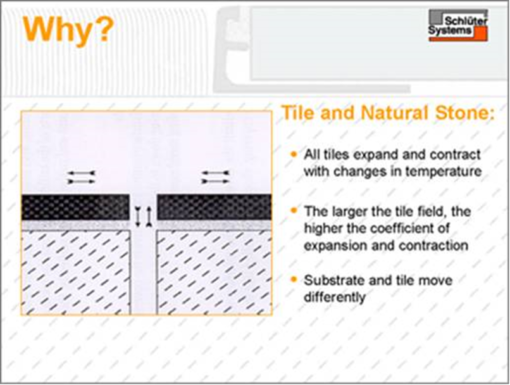

Expansion and Perimeter joints are needed because all tiles expand and contract with temperature and moisture changes. In almost every case, the substrate will move differently to the covering material. The larger the tile field, the more it will expand and contract, and be vulnerable to failure. Movement joints accommodate the differential stresses within each “field” of tiling, so they don’t build up to a level which would cause shearing stresses at the bonded interface, protecting the tiles from cracking, tenting and debonding.

Stresses from drying shrinkage; deflection and moisture movement in the substrate; plus thermal and moisture changes, affecting the flooring, can cause loss of adhesion, resulting in bulging or cracking of the floor. Building movement may occur due to changes in conditions, physical movement due to size, settling or drying out of the building, weight loading, level of trafficking, thermal changes or simply due to the construction design itself.

In particular, deflections in suspended floors can induce high compressive stresses in rigid floor tiling, and may be the principal cause of “hollowness” in those situations. The shear stress resulting in the substrate and ceramic moving differently from each other is often too great for the adhesive to hold – shown in the top picture.

Therefore, stress-relieving joints are an essential part of any tiling installation, and should be incorporated at the design stage.

Location

- Floors – movement joints should be provided:

- Over existing and/or structural movement joints

- Perimeter joints (minimum gap of 5mm) should be inserted at door thresholds and next to surfaces such as perimeter walls, columns, curbs and steps

- In larger internal floor areas, intermediate movement joints should be provided to form bays of size not greater than 10m x 10m (where large degrees of thermal movement or vibration are expected, the frequency of movement joints should be increased to accommodate the movement)

- In larger external floor areas, intermediate movement joints should be provided to form bays of size less than 10m x 10m

- On suspended floors, stress relieving joints should be inserted where flexing is likely to occur, e.g. over supporting walls or beams

- Internal floors, which might be subjected to significant thermal changes, i.e. direct sunlight or underfloor heating etc, the floor area should be divided up by intermediate movement joints provided at 5m intervals in both horizontal directions to provide 25m2 bays.

Consideration to the use of a tiling movement joint must be given in all of the following areas:

- They must be incorporated and aligned with any movement joints within the floor’s construction. The joints should be continued through the entire depth of the tile and adhesive.

- At specified distances across a floor to create individual tile beds (general consensus is that movement joints should be utilised at distances between 5m and 8m).

- Movement joints should be placed directly above any supporting walls or structural beams as they will add rigidity to the floor. The remaining floor area may be prone to a degree of flex or vibration.

- Junctions between floors and walls.

- Internal Walls – movement joints should be provided:

- Over existing and/or structural movement joints

- Where tiling abuts other materials

- Where tiling is continuous across junctions of different background materials

- In large tiled areas, at internal vertical corners and at 3m to 4.5m centres horizontally and vertically (where large degrees of thermal movement or vibration are expected, the frequency of movement joints should be increased to accommodate the movement)

- Where stresses are likely to be concentrated, for example at changes of alignment

- Movement joints should be of a suitable width to permit the sealant to accommodate the expected movement (typically 5mm).