In parts 1 and 2 of ‘How to Read a Tile Specification’, we examined the dimensional tests, water absorption and structural tests. In the third and final part, we’ll look at slip resistance – a crucial factor for installing tiles in outdoor areas, commercial kitchens, bathrooms and commercial spaces where slipping can be a hazard and a legal issue.

Slip Resistance

Item 15 tests for Slip resistance. Floor slip resistance testing is the science of measuring the Coefficient of Friction (CoF) of flooring surfaces, either in a laboratory or on floors on site. Flooring is tested using a tribometer (a floor slip resistance tester) to determine if there is a likelihood for slip and fall accidents, either dry or most often when wet with water or lubricated with other slippery substances.

A Static Coefficient of Friction (SCoF) is unreliable. Often used in the US for assessing safety, SCoF measurements are often misleading where flooring gets wet or otherwise lubricated in use. The Ceramic Tile Institute of America and the Tile Council of North America have ruled the method to be inadequate for assessing slip safety. The slipperiness of flooring materials can change significantly due to the installation process. For instance, grouting; cleaning or polishing; inappropriate maintenance or longer-term wear also change the slip resistance of flooring. Data quoted simply as CoF should be viewed with uncertainty. DCoF means Dry Coefficient of Friction.

Three Viable Methods:

The Pendulum Tester

This is a national standard for pedestrian slip resistance in 49 nations. It is the most widely used pedestrian slip resistance test method worldwide. The pendulum uses a standardised piece of rubber, which is set up to travel across the flooring sample mounted onto a pendulum device.

A Digital Tribometer

This is used as the test instrument for America’s ANSI B101.3 test standard, which measures dynamic friction at a lower speed than the pendulum. This particular tribometer, a BOT-3000, is also a drag-sled meter, which means that it crawls along the floor under its own power at a constant speed measuring the resistance to slip of a standardized piece of rubber loaded into the bottom of the machine.

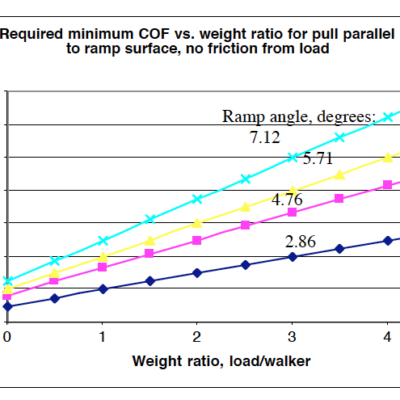

The Variable-Angle Ramp

This is a German-developed method for obtaining pedestrian slip resistance values. Flooring samples are mounted horizontally on the ramp tester and an operator clad in safety boots or bare feet performs a standardised walk up and down the sample while wearing a harness to stop the operator from being injured. The sample is slowly inclined until the operator slips on the surface. The angle at which the subject slips is then recorded. Two operators repeat this test three times and then an average is calculated. The repeatability of this test method is reliable.

Co-efficient of slip resistance: dry vs. wet surfaces

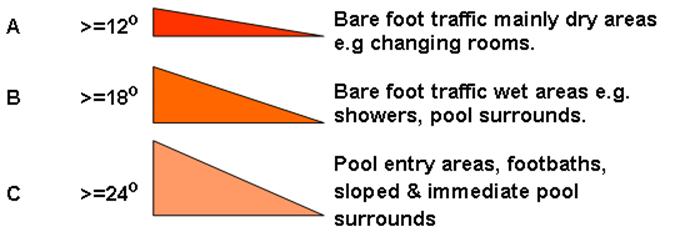

Dry slip resistance is not an indicator of wet slip resistance, in fact, the two often vary inversely. Therefore, reliable wet slip resistance testing is often needed as well as reliable dry testing. Slip resistance is tested both with footwear and barefoot. This is especially important when testing areas which are normally sloped and/or wet such as swimming pool surrounds or exterior access ramps. In the tile industry, an ‘R’ rating is used to indicate slip resistance. This rating correlates with an angle of inclination; the steeper the angle, the higher the slip resistance and the higher the R rating. US standards require a minimum Dry CoF of 0.42.

R rating for dry surfaces Recommended for

Slip resistance groups:

Barefoot on wet surface. Recommended for

If you have any technical questions relating to tiles, you are most welcome to contact our Tiletoria Showroom’s to speak to our experts. Our experts offer technical training that is available online or in office with your architectural team. We are also SAIAT accredited to issue CPD credits.