In today’s commercial and residential applications, large format tiles are all the rage. Designers like the aesthetically pleasing, open look it gives floors and walls. But large-format tiles also have their installation challenges, one of them being that these tiles require tighter tolerances in the substrate. In addition, its weight makes it harder to handle in both floor and wall applications.

Modern manufacturing techniques have allowed the production of large format porcelain tiles with a high degree of accuracy in size and shape.

Because all manufactured materials have a degree of tolerance in production, installation materials and systems have been developed to enable the best possible results to be achieved more easily.

Common challenge concerns of installing large format tiles are:

Tile weight

Heavy floor tiles that settle into the adhesive beds can cause lippage (height difference between adjoining tiles). It is crucial to achieve secure bonding of the substrate and the tile. Applying an insufficient amount of adhesive may result in hollow sounding spots. The hollow spot is susceptible to damage from concentrated weight because of a lack of support from the adhesive in that area of the tile.

Cracking

Cracking is a possibility if the tile is bonded directly to concrete (insufficient adhesive). This is because cracks naturally occur as water in the concrete substrate evaporates. These shrinkage cracks can transfer from the substrate and into the bonded tile.

Levelling Systems

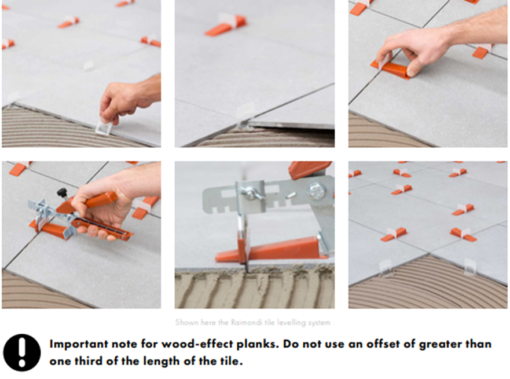

It’s almost undeniable that an excellent tile levelling system can prevent lippage, mainly when dealing with more significant format tiles. Due to the design, tile-levelling systems intertwine the tiles, making sure the surfaces stay flat and smooth while the thin-set dries. Not only does the interlocking design lower the likelihood of lippage, but it can minimise or eliminate shrinkage or settling. Apart from the prevention of lippage, a tile levelling system can also shorten the installation time by discarding the need for lifting some of the tiles to increase thinset.

An entire levelling system has three chief components: clamps (spacers), wedges, and pliers. These elements work in unison to avoid the movement of tiles while the compound is setting as well as enhancing the flatness of the surface.

All levelling installation systems combine the use of spacers (to provide consistent grout joint gap) with a method of applying constant pressure over two or more tile edges to keep them as even as possible. Better systems are able to apply more pressure and more consistent spreading of pressure over multiple tiles.

It is important to understand that there are different types of systems available with differing capabilities. Within these different types, there are also larger and smaller sizes that are typically intended for tiles of differing thickness, up to 20mm.

Therefore, these systems assist with:

- Minimising any lippage (height difference between adjoining tiles)

- Evening out minor variations in the substrate

- Evening out minor variations in the tile shape

- Evening out minor variations in the adhesive

- Maintaining consistent joint width

Levelling Systems are available from Tiletoria:

Please see the below links of the products available:

The YouTube video link below is an example to show you the correct setting methodology.

Porcelain tiles 2’x4′ (24″x48″) installation – Polmaster’s New Showroom